Our Services

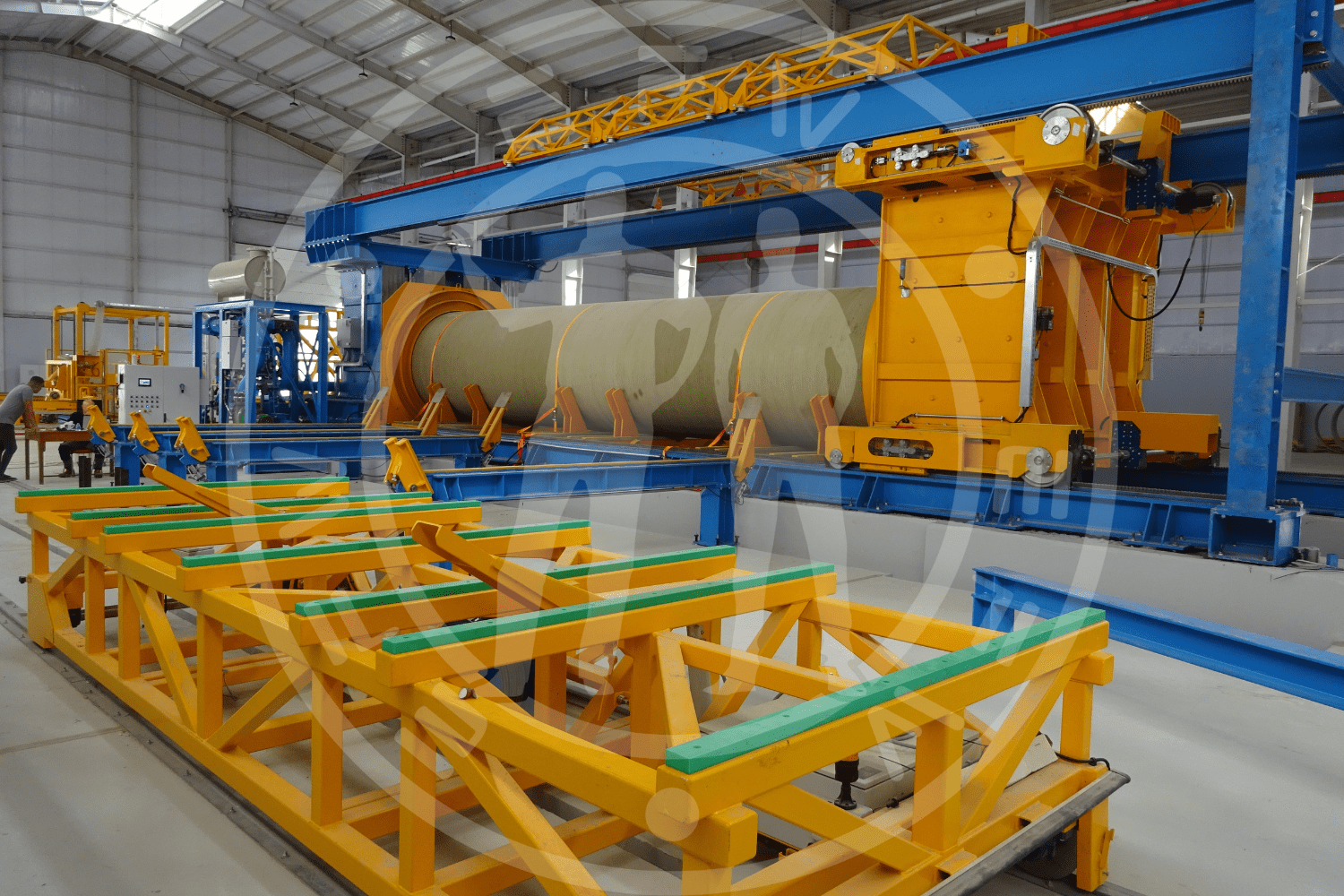

Get your new E-CFW Production Lines

Get your new, complete and effective E-CFW production lines from the design to the installation and improve your company’s profitability.

Design

In the composites business, it is of the utmost importance that the production line is built for the GRP product you want to produce, in line with the specific market needs.

You need to analyze your market requirements, study the exact design for your product, and only then tailor your production line based on that information.

Our E-CFW LINES are tailor-made for your needs and offer the best support for our EFW® Technology and includes all the equipment to:

- reduce downtime’s, through the advanced machine set up,

- reduce scrap levels, through our EFFECTIVE FILAMENT WINDING® 100% analytical approach and methodology,

- reduce GRP pipe manufacturing costs, through precise control of raw material processing.

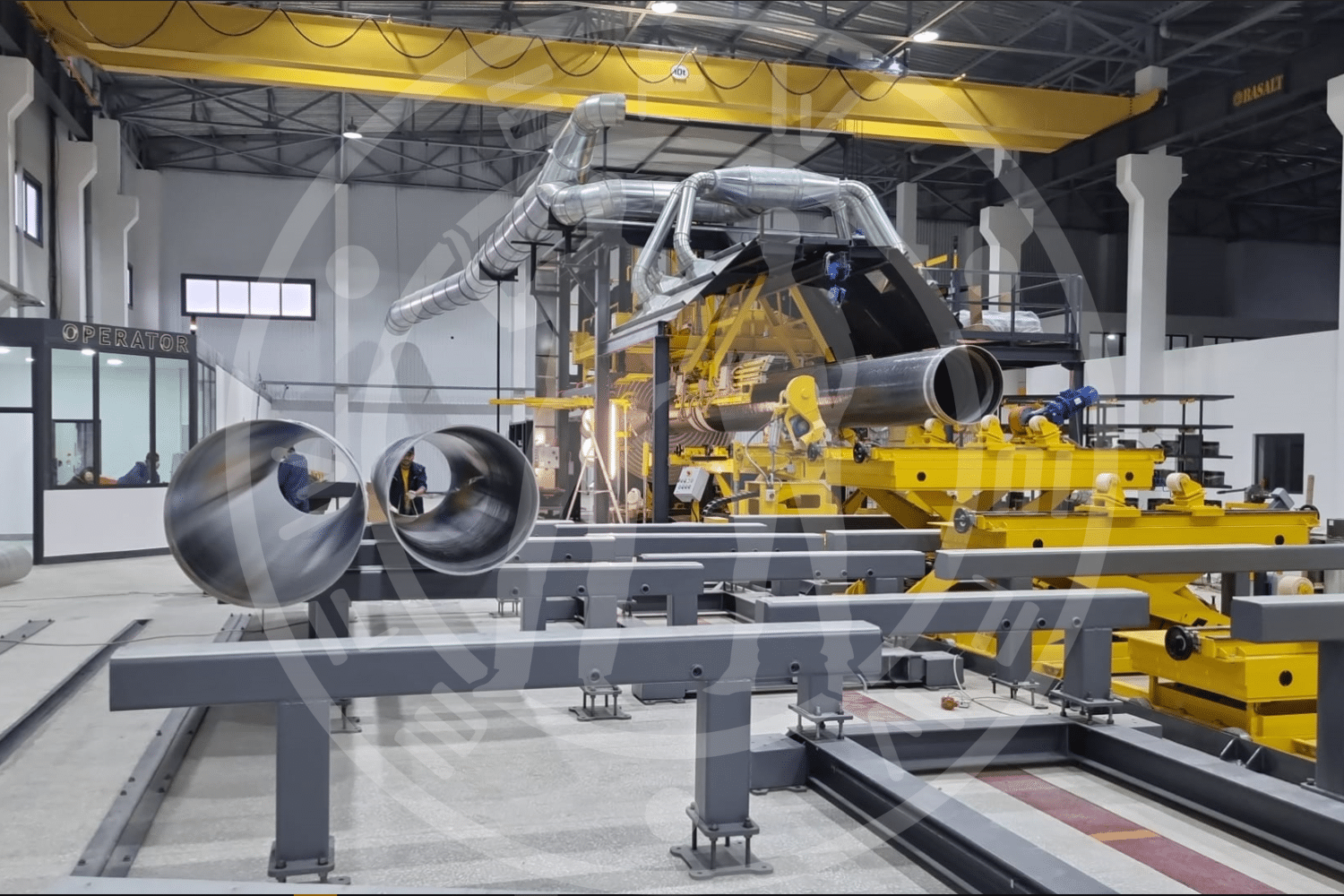

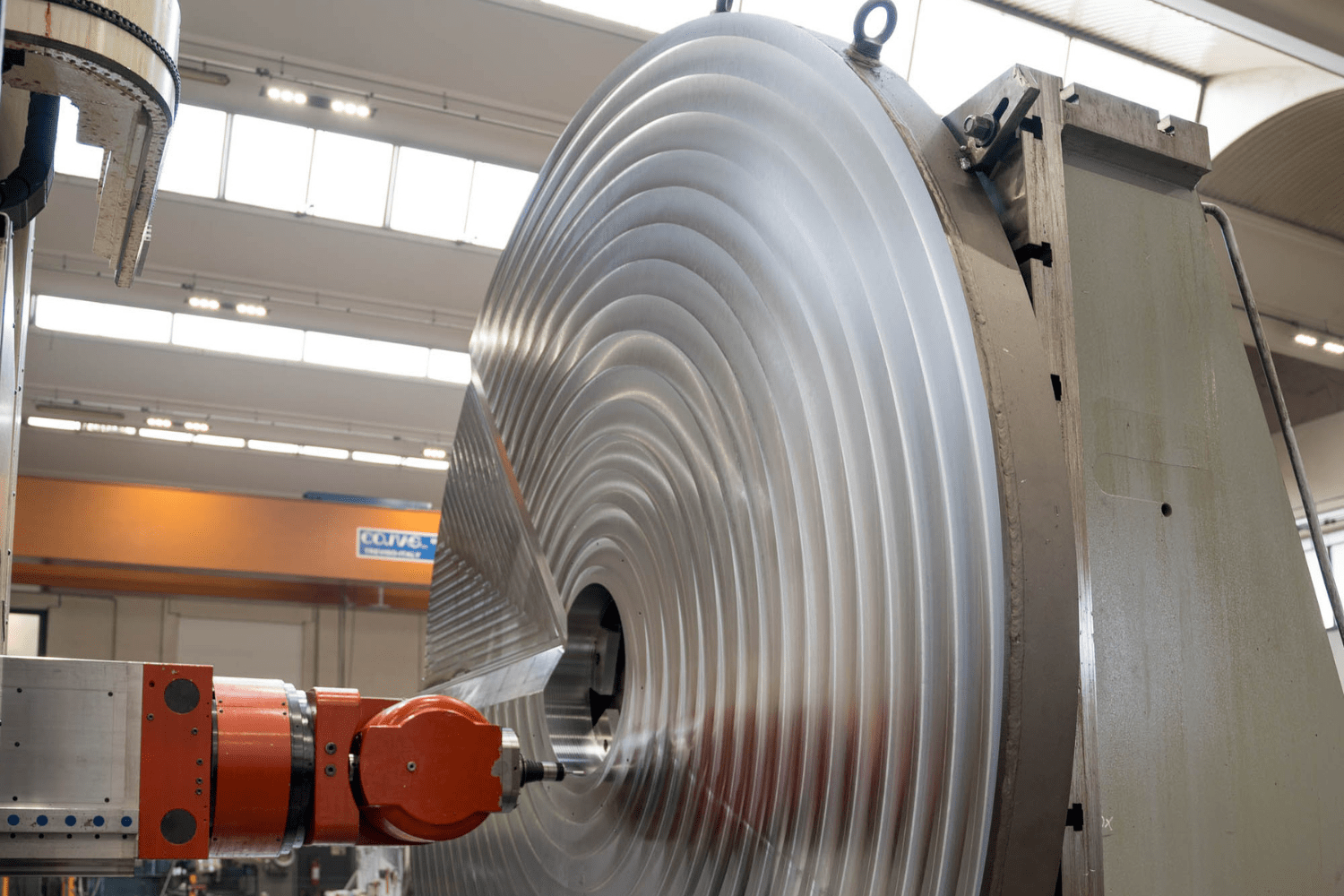

Manufacturing E-CFW Lines

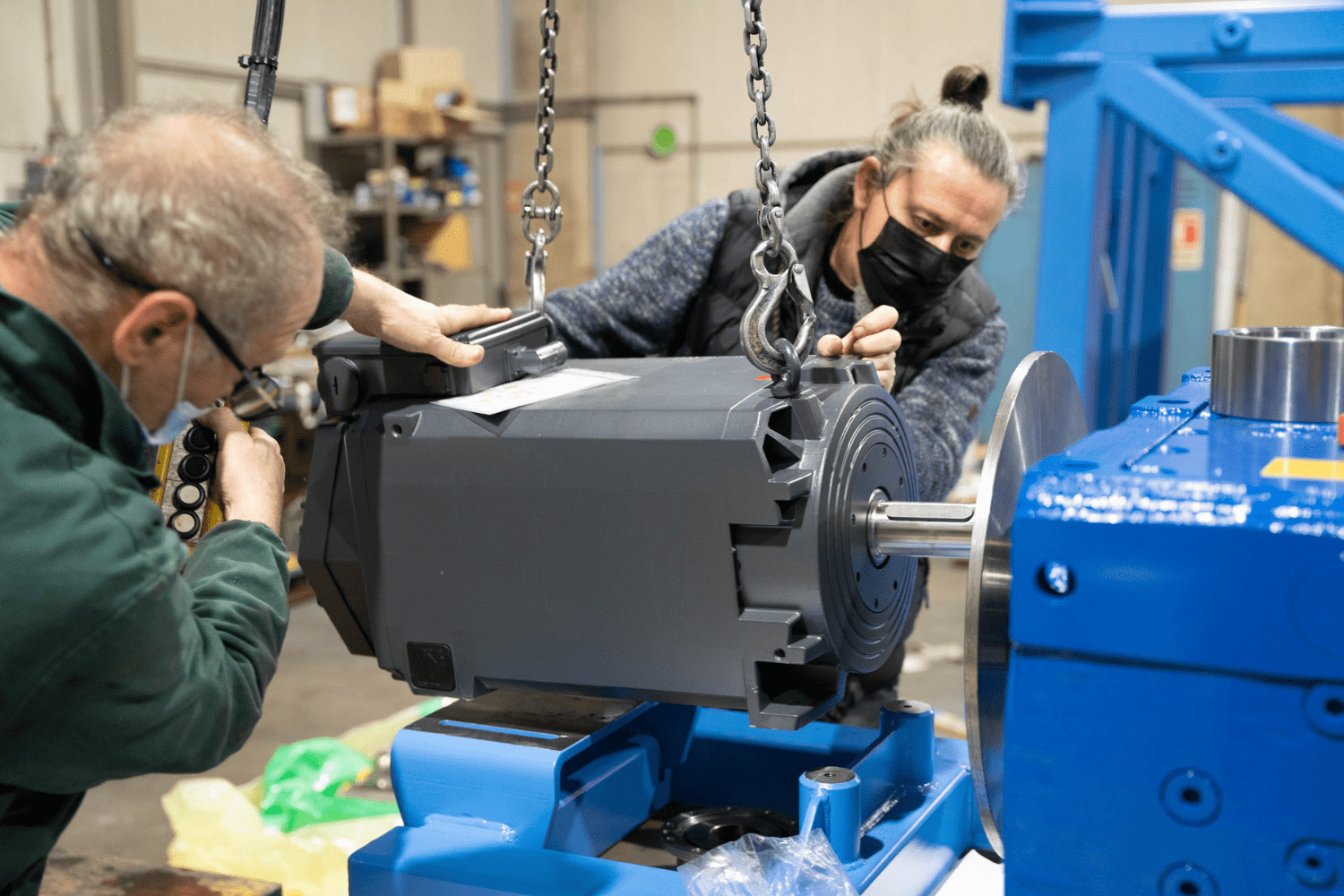

We follow very strict quality control procedures in TOPFIBRA, because in our EFFECTIVE FILAMENT WINDING® LINES, each detail plays an important role for the final process optimization.

For this reason, we always insist on personally checking the key components of our high-performance Continuous Filament Winding

(E-CFW LINES).

If you are planning to invest in this industry, our advice is to be very careful when choosing the manufacturing line, because the choice between high-performance equipment or standard equipment will strongly influence your return of investment.

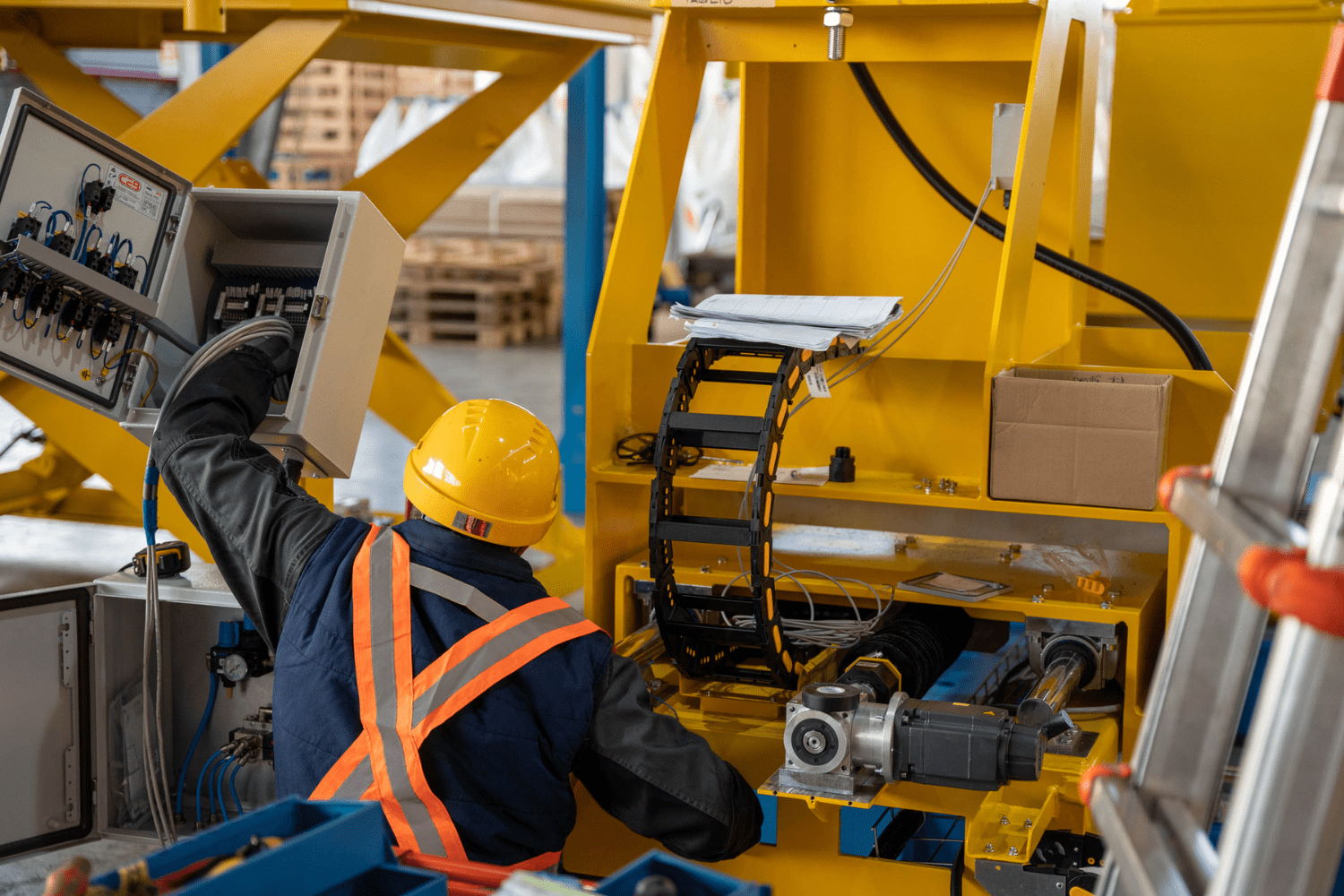

Installation and Start Up

This service consists of a skilled supervision of the works relevant to the erection, start-up, and commissioning of the plant. A detailed schedule is agreed upon by the signature of the supply agreement.

These services are provided by a team of experts with the following qualifications:

- Mechanical Superintendent,

- Electrical & Automation Superintendent,

- Process & Chemical Engineer.

Some TOPFIBRA technicians have more than one qualification, and thus are able to perform different services during installation.

The Customer shall provide the necessary skilled personnel to be trained by our specialist, tools, lubricants for the first filling (grease, oil) as per the quantities agreed by the signature of the supply agreement. The training of the plant personnel will be organized in such a way so as to render it autonomous in operating the plant by the time of its commissioning.

Commissioning of E-CFW Lines

The commissioning service is the procedure aimed at demonstrating the operating characteristics of the Equipment, which includes set-up operations, preparation for production, and trial production as well as the effectiveness of the transferred Know-How.

TOPFIBRA will supply the Customer with a list of standards and specifications relevant to the technological process as well as all the software to integrate all the activities as per our EFW® Technology.

We will also supply you with:

- advice on the manufacturing techniques and optimum use of the Customer’s machinery and equipment,

- advice on the execution of short and long-term testing on the product, the execution of Hydrostatic Design Basis (HDB) according to ASTM standards,

- sourcing of raw materials supply,

- technical audit and evaluation of the Customer’s plant and recommendations for improvement.

Send us Your Specifications to Start Your New GRP Project!

Subscribe to our newsletter

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production.