A Continuous Winder can, for example, produce an ND 2600 GRP pipe at a production rate higher than 16 meters/hour with only a few workers. But when we analyze the fitting department working on the ND 2600 fitting production (doing an elbow, tee or another type) we are given quite a shock:

a lot of workers need to be involved in the job, we see fiberglass dust flying all over the place, the efficiency is extremely low and workers are exposed to injuries and other health hazards.

- If I told you that you can cut the same pipe in just a couple of minutes instead of nearly 4 hours, getting an accurate cutting of pipe ends, segments and cut-outs, would you believe it?

- And if I added that there will not be any risks of injury and health hazards because the operator can stand far away during the cutting?

- And finally that it is possible to perform any type of cuts for any type of fitting?

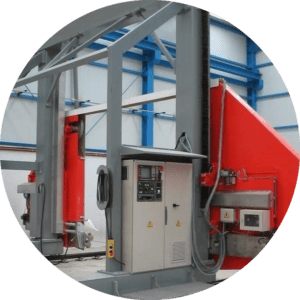

Yes, it is possible, the solution is right here. The marking and cutting operations for fittings can be optimized by utilizing an innovative GRP pipe cutting technology, the so-called Fittings Cutting Station.

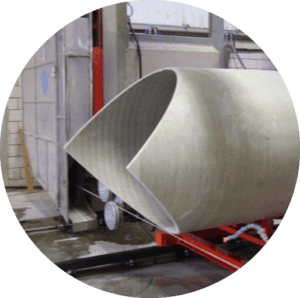

The Fittings Cutting Station (FCS) enables accurate and rapid cutting (within minutes) of pipe ends, segments and cut-outs for fitting manufacturing operations.

After the installation, the efficiency of the manufacturing of the fittings will increase by more than 50% and furthermore, the factory will avoid costly and labor-intensive stages, complicated marking of pipes, risks of injury, and health hazards related to dust generation.

Execution of a precise cut-out for a TEE branch

Another very important piece of information: after the installation of the FCS, you will be able to forget about the Four Hidden Dangers of frequent manual cutting of GRP pipes for fittings.

If you want to increase your profit, I will assist you in making the optimal choice for your exact production needs and will provide you with a turnkey solution that includes project management, installation, commissioning, and training.

Feel free to contact me by simply completing the form below.