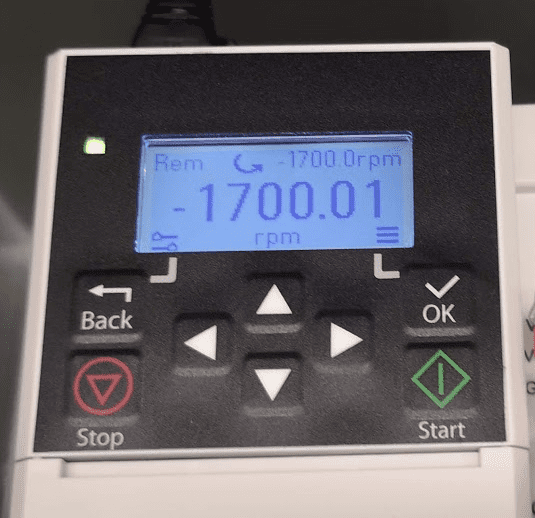

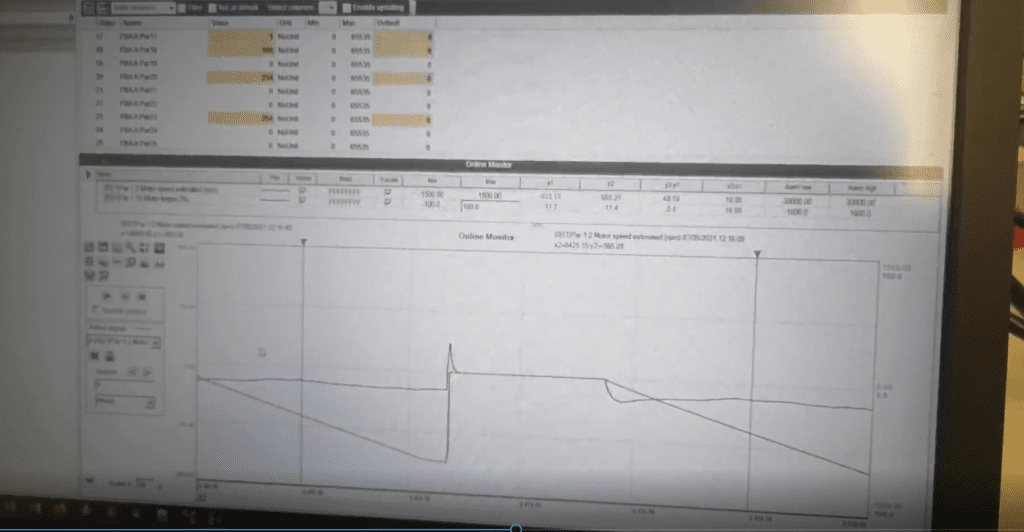

After the successful performance test, the E-AD4000 Stand-Alone Accelerator System is ready for shipment.

The most regular occurrence of pipe damages is seen during the cutting of a pipe, in the final rotation cycle.

In fact, it is the difference in relative rotation during the cutting and the pipe that will be discharged, that will cause a tear on the liner.

Due to the difference in relative rotation if the pipe is not handled correctly, a tear on the liner will appear, thus compromising the water tightness of the pipe, and a possibility of a breakage of the cutting blade will arise.

This is why, it is important to have excellent control of the pipe handling. We assure it with the new CFW technology upgrade.

If you use a standard CFW technology, you know how crucial the cutting cycle in your machine is.

Why are our customers upgrading their CFW equipment with the E-AD4000 Accelerators?

- High Precise Speed Control: extremely important to protect the spigot during the final rotation cycle

- Full Torque and Acceleration Control for the production of small and big pipe diameters

- High Tilting Accuracy

Implement NOW the E-AD4000 PLC CONTROLLED ACCELERATOR in your Standard CFW machine.

Click on the link below to discuss your next upgrade with us: