In the fast-paced world of infrastructure development, every choice you make—from the materials you pick to the tech you use—really counts towards your profits. As a high-level entrepreneur who’s all about smart investments, you’re not just buying products; you’re looking for solutions that deliver big returns on investment (ROI).

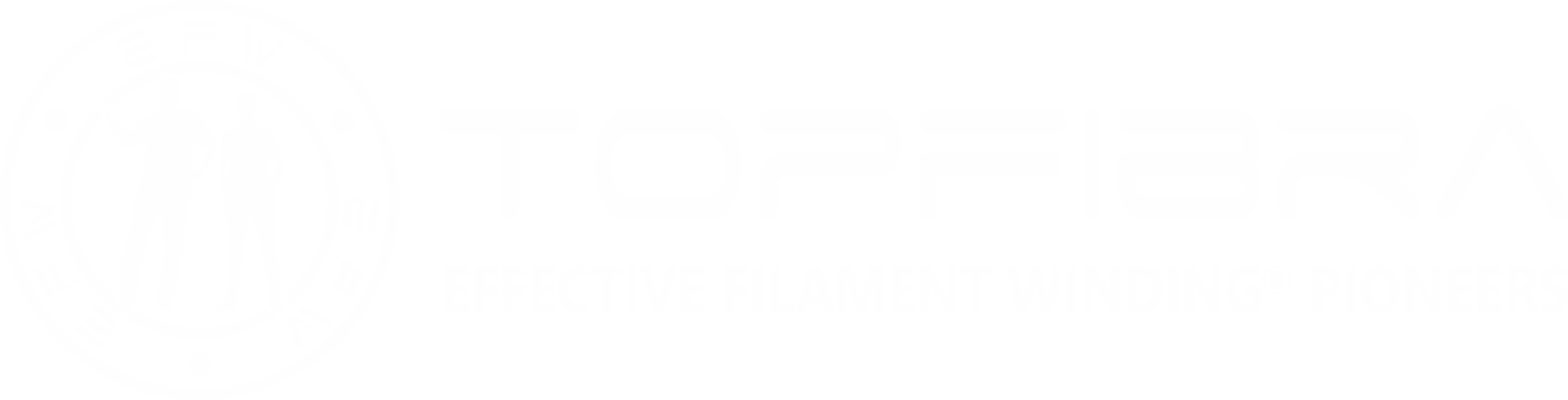

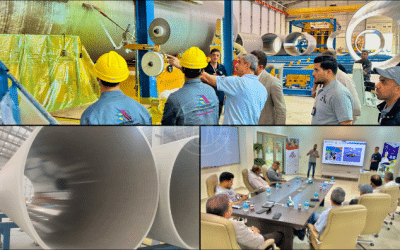

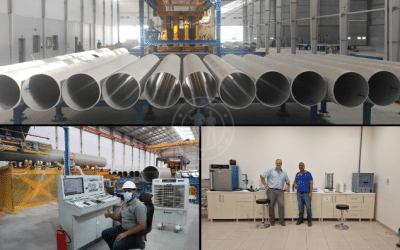

Glass Reinforced Plastic (GRP) pipes are a game-changer if you want to future-proof your projects and get the most profit.

If you want to learn more about how to Boost ROI with GRP Pipes, read more in the latest blog post.