News

Latest Topfibra News

We’re eager to share that our team successful completed the Dry Test of our Next-Generation E-PHTM Pipe Hydrostatic Testing Machine

Our R&D team and engineers have pushed the boundaries once again, further reducing cycle times and enhancing overall performance.

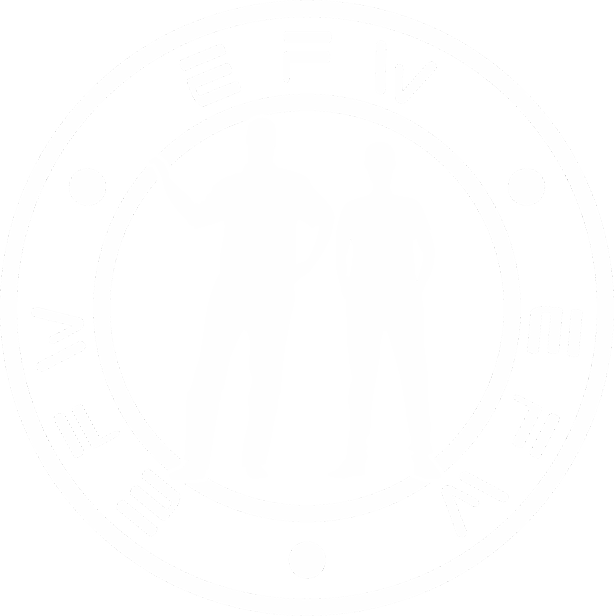

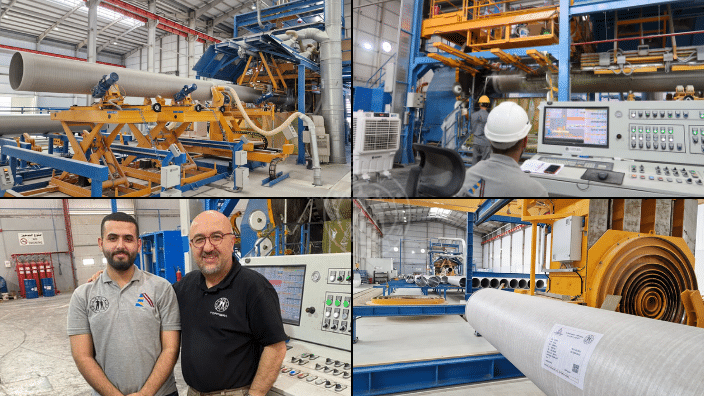

Welcoming the Baghdad Water Authorities to the Basra Plant

The Topfibra and Al Nargis teams demonstrated the optimal performance of our GRP products, highest on the market.

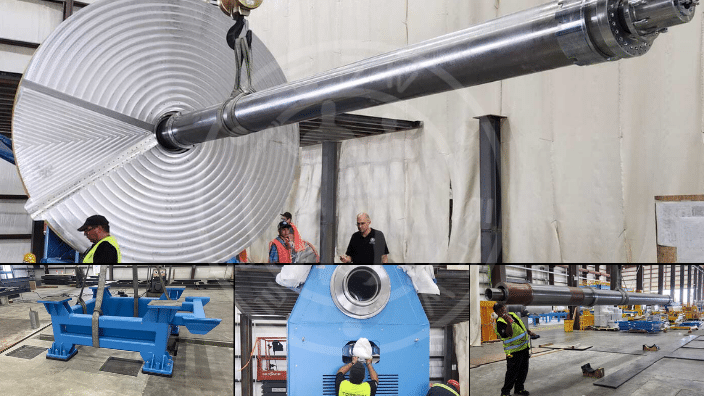

New blog post: Preparing Your Team for Effective Filament Winding Operations

Investing in state-of-the-art equipment is crucial for success in GRP pipe manufacturing, but it's only part of the equation.

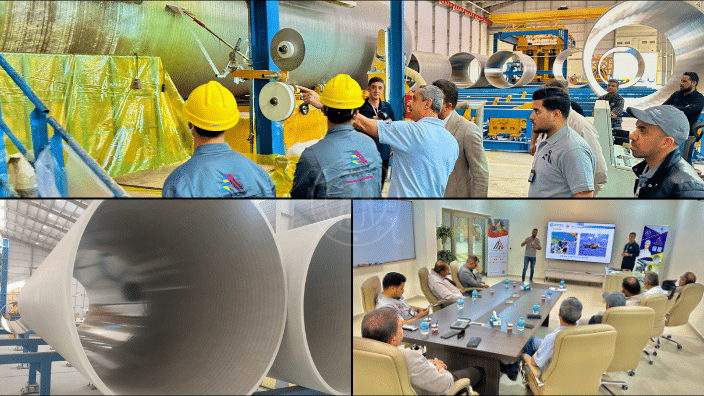

Installation of the second E-CFW Line in Texas, USA

We are thrilled to announce the commencement of the installation of the first phase of our second E-CFW Line in Texas.

Topfibra Welcomes New Project Manager

We are excited to welcome Antonio Sponziello to the Topfibra team as our new Project Manager.

New blog post: Debunking Three Common Myths About GRP Pipes

As a CEO or plant manager, you're always juggling quality, efficiency, and cost. In the dynamic field of industrial construction, picking the right materials can make or break your project's success.

New blog post: Difference Between Continuous Filament Winding and Effective Filament Winding

If you're a CEO or a plant manager, understanding this distinction is crucial for building a truly profitable GRP business.

Visit of ASF Company in Al Nargis

We took great pride in the opportunity, alongside our esteemed partner Al Nargis, to present our unique Effective Filament Winding analytical approach to the Italian ASF company.

Subscribe to our newsletter

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production.