What is GRP?

GRP, or Glass Reinforced Plastic, is a high-performance composite material made by embedding fine glass fibers into a durable polymer matrix, typically a high-grade plastic resin. Commonly known as fiberglass, GRP combines the structural strength of glass with the versatility of modern resins, making it the foundation for advanced GRP pipes used worldwide.

This advanced material offers exceptional strength, long-term durability, and outstanding corrosion resistance, all while maintaining a remarkably lightweight profile.

Thanks to these properties, GRP is an ideal choice for manufacturing high-performance GRP pipes used in water supply, wastewater management, energy infrastructure, and various industrial applications.

With a lifespan of 120 years and minimal maintenance requirements, GRP ensures reliable performance and reduced lifecycle costs in even the most demanding environments.

What are GRP Pipes?

GRP pipes are high-performance piping systems made from Glass Reinforced Plastic, designed to transport potable water, wastewater, industrial fluids, and other media safely and efficiently. Engineered for maximum efficiency and minimal maintenance, they feature high mechanical strength, a smooth internal surface, and exceptional chemical resistance. GRP pipes outperform traditional steel, ductile iron, and concrete pipes in durability, ease of installation, and overall lifecycle cost.

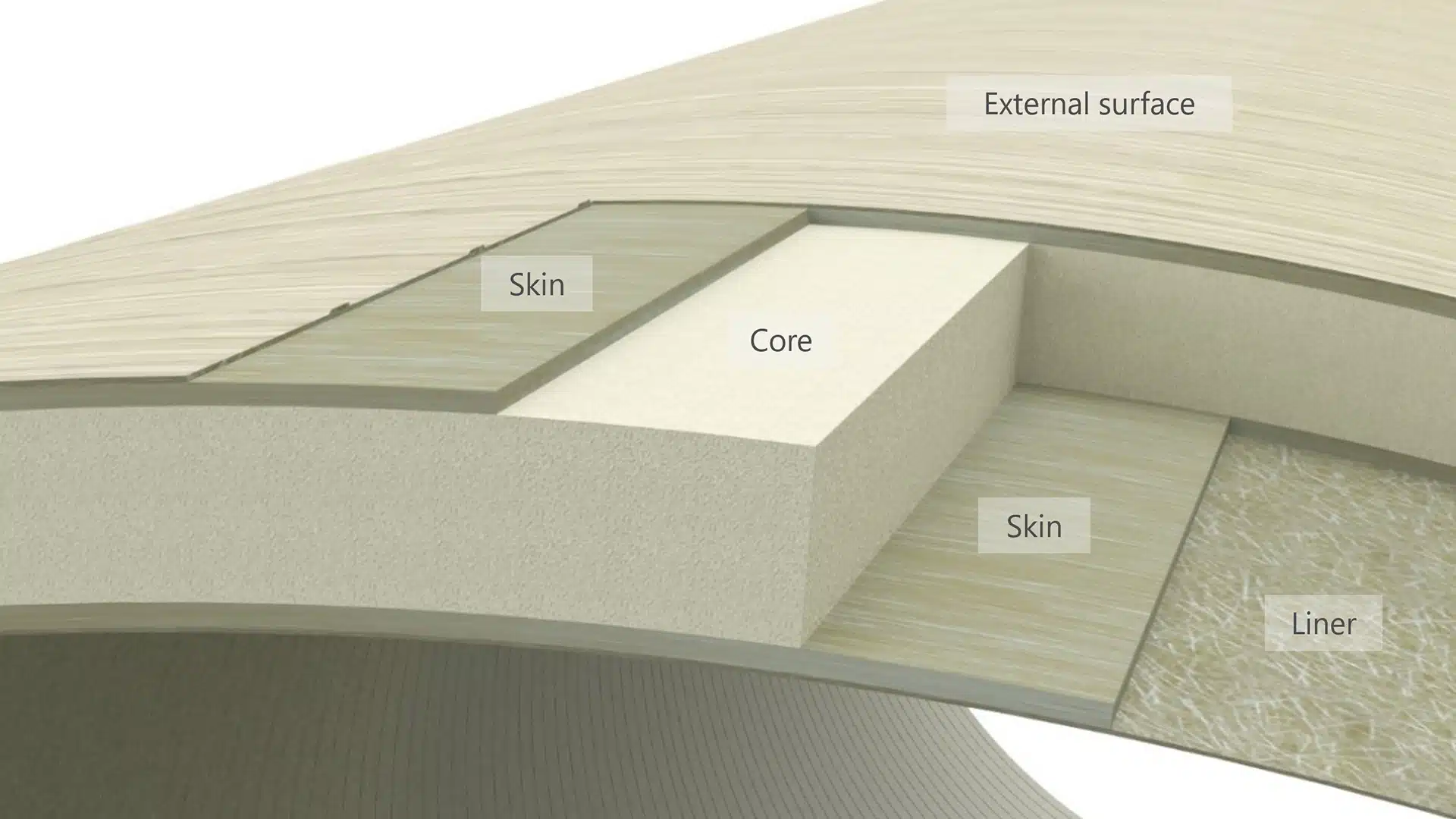

The composition of a GRP pipe is made of three key layers, each serving a specific purpose:

- Internal Layer (Liner or Chemically Resistant Layer)

This layer is in direct contact with the fluid. With a high resin content, special resins, and specific glass reinforcement, it ensures maximum chemical resistance and complete impermeability. Standard thickness ranges from 0.8 to 1.2 mm, but it can be increased if required.

- Mechanically Resistant Layer (Structural Layer)

The core layer of the pipe is reinforced with a high content of glass fibers to withstand internal pressure, external loads (soil, traffic, thermal expansion), and installation stresses. This layer ensures the pipe’s mechanical strength and long-term stability.

- Outer Layer (Topcoat or Gel Coat)

A protective resin layer, often with a UV inhibitor, that shields the pipe from sunlight, weather, and environmental exposure. The typical thickness is 0.2–0.3 mm or more, depending on the design requirements.

What is GRP Coupling?

A GRP pipe coupling is a reliable method for joining GRP pipes, creating a strong, flexible, and leak-proof connection. In pipelines made with Continuous Filament Winding (CFW) technology, it keeps the system secure and makes installation faster and easier.

There are two types of GRP pipe couplings, each suited for specific applications:

- Reka Gasket Coupling

A fast, leak-proof joint using two durable EPDM rings that adapt to ground movement and misalignment. Best for non-flanged connections where speed and reliability are most important.

- SealPro Coupling

A leak‑proof flanged joint with a factory‑bonded EPDM gasket that excels under high pressure and corrosive conditions. Ideal for flanged connections in potable water, industrial, and wastewater networks.

GRP pipes are up to 70% lighter than concrete and 30% lighter than steel,

helping you finish projects sooner and lower installation costs.

What are advantages of GRP (Glass Reinforced Plastic) Pipes?

Corrosion Resistance

GRP pipes are highly resistant to corrosion, making them ideal for transporting corrosive fluids such as chemicals, sewage, and saltwater. This durability ensures a longer service life and reduces maintenance costs.

Lightweight

Significantly lighter than steel or concrete, GRP pipes are easier to handle, transport, and install, lowering labour and equipment costs on every project.

High Strength-to-Weight Ratio

Despite their lightweight, GRP pipes offer exceptional structural integrity and can withstand high-pressure conditions, making them suitable for a wide range of applications.

Smooth Interior Surface

A smooth internal surface minimises friction, allowing efficient fluid flow, reducing energy consumption in pumping systems, and maintaining high flow rates over time.

Long Service Life

When properly installed and maintained, GRP pipes can last over 120 years, providing a durable solution that reduces replacement and maintenance needs.

Chemical Resistance

GRP pipes can withstand a wide range of chemicals and aggressive substances, making them the ideal choice for demanding industrial applications.

Low Thermal Conductivity

Their low thermal conductivity minimises temperature-related expansion and contraction, ensuring stable performance for both hot and cold fluid applications.

Versatility

Available in various shapes, sizes, and configurations, GRP pipes can be customised with additional layers or linings to meet specific project requirements.

Ease of Installation

Supplied in long lengths, GRP pipes require fewer joints, which simplifies installation, reduces the risk of leaks, and speeds up project completion.

Low Maintenance

With no rust, corrosion, or significant scale buildup, GRP pipes require minimal upkeep throughout their lifespan.

Environmental Benefits

Made from non-toxic materials and recyclable, GRP pipes are an eco-friendly choice. Their long service life further reduces waste and environmental impact.

Corrosion-resistant GRP pipe solutions designed for the harshest environments.

Where Can GRP (Glass Reinforced Plastic) Pipes Be Used?

GRP pipes are adaptable to an extensive range of uses, making them a preferred choice for both public infrastructure and industrial projects:

Wastewater Solutions

Corrosion-resistant systems for municipal sewage and treatment plants

Potable Water Systems

Safe, hygienic delivery of drinking water with no risk of leaching harmful substances.

Sewer and Drainage Systems

Durable, low-maintenance solutions for urban infrastructure.

Irrigation Networks

Efficient distribution of water for agriculture, with minimal losses.

Hydropower Projects

High-pressure GRP pipes designed for long-term performance in demanding environments.

Industrial Applications

Resistant to chemicals and suitable for transporting various industrial liquids.

Jacking Pipes

Ideal for trenchless installations, minimising surface disruption in dense urban areas.

From urban water networks to renewable energy projects, GRP pipes deliver reliable performance in diverse environments and climates.

GRP pipes deliver 120+ years* of reliable service with minimal maintenance,

proven in water, wastewater, energy, and industrial infrastructure projects.

*The required practice is to define projected performance limits at 50 years, but the expected life of EFW Technology pipes is 120+ years.

What GRP Products Can You Manufacture with E-CFW Lines?

Our E-CFW Lines are capable of producing a complete range of GRP pipe products:

Pressure pipes

Engineered for high-pressure applications in hydropower, potable water, and industrial systems.

Non-pressure Pipes

Cost-effective solutions for gravity-fed wastewater and drainage networks.

Jacking Pipes

Designed for trenchless installations, offering precision, strength, and durability.

Joints & Couplings

Secure, leak-free connections for long-term reliability.

Fittings

Custom-designed to meet specific system layouts and operational needs.

Every pipe produced on our lines meets international quality standards and is tailored to deliver optimal performance for its intended use.

What Makes GRP Pipes a Profitable Investment?

GRP pipes combine exceptional performance, long service life, and versatility, making them a smart choice for infrastructure projects worldwide. As the backbone of water supply, wastewater, energy, and industrial systems, they deliver over 120 years of reliable service with minimal maintenance, even in the harshest environments.

For investors, understanding the final product of your E-CFW production line is key to evaluating its long-term value. GRP pipes are lighter than concrete and steel, reducing transportation and installation costs. Their corrosion resistance and smooth interior ensure efficient operation and lower lifecycle expenses.

When manufactured with our advanced EFW® Technology, GRP pipes meet the highest global standards, deliver predictable performance, and maximise return on investment by producing infrastructure that lasts for decades.

Ready to see how GRP pipes can maximise your investment?

Explore the technology behind the world’s most profitable production lines.

Customizable in size, shape, and configuration,

GRP pipes adapt to the most demanding project requirements.

Learn more in our EFW® Blog

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production

We created a unique blog so you can read all about our EFFECTIVE FILAMENT WINDING® Technology in one place!

It is the FIRST and ONLY blog, dedicated exclusively to the EFW® TECHNOLOGY, which is the first and only approach that allows profit optimization in the Filament Winding industry.

You can read all about the implementation of the EFW® Technology, how it connects all stages of your production and ensures that you are able to produce the best possible product and increase your profit.

Click on the button below, bookmark our blog and be up to date with our exclusive articles dedicated to the EFFECTIVE FILAMENT WINDING® Technology.

Subscribe to our newsletter

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production