Effective Filament Winding® Lines

Most Profitable Continuous Filament Winding Lines in GRP Production

The E-CFW Lines. Powered by EFW® Technology. Engineered for Profit.

The E-CFW production line is your complete solution for high-performance GRP pipe manufacturing. It delivers efficiency, precision, and long-term reliability through advanced

EFW® Technology and supports pipe diameters from ND 300 to ND 4000 mm.

Each E-CFW Line includes:

-

-

-

-

-

Production Equipment

-

Ancillary Equipment

-

Testing Equipment

-

Laboratory Equipment

-

-

-

-

We manage your E-CFW Line project from start to finish, including design, manufacturing, logistics, installation, and EFW® technology transfer.

You get a fully integrated solution backed by proven expertise, so you can start producing high-quality GRP pipes with confidence and profitability from day one.

The only GRP line proven to save you over €1,000,000 a year.

Why the E-CFW Line Outperforms Standard CFW Lines in GRP Pipe Production

Discover how EFW® Technology transforms GRP pipe production

Exceptional Output

Produce over 21,000 tons of GRP pipes per year with a single line. This is equivalent to more than 250 kilometers of ND 900 pipe annually.

Lowest Cost per Meter

Proven annual savings of over €1 milion, thanks to highly optimized energy use, material efficiency, and automation.

Reliable, Heavy-Duty Performance

Our equipment is tested under real industrial pressure. Designed for continuous operation, with minimal downtime and a long service life.

Fast Changeover System

Diameter changeover time reduced by over 55%, increasing effective production hours and overall plant performance.

Ultra-Low Scrap Rate

With less than 0.4% industrial waste, nearly every meter produced is ready to sell, meaning maximum profit per ton.

Certified and Co-Branded Production

Pipes produced with EFW® technology are certified and labelled with both your brand and ours proof of quality your clients will trust.

On-Site Expert Support

We deploy our specialists into key positions within your production team to ensure maximum efficiency, training, and success.

Smart, Data-Driven Control

Real-time data and KPIs are monitored throughout the process, enabling continuous optimization and repeatable, profitable results.

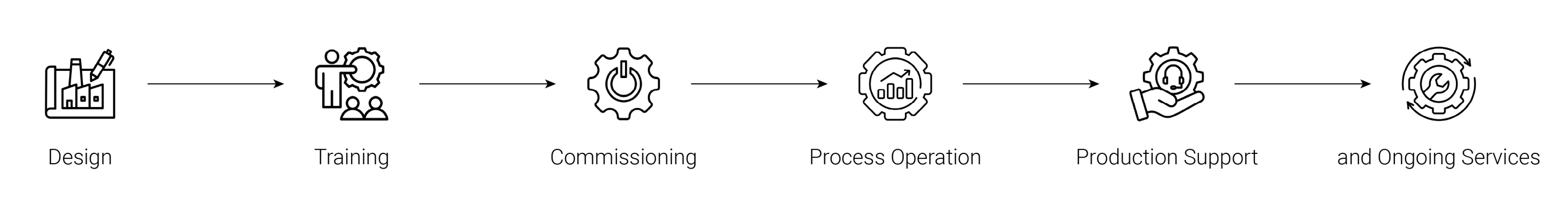

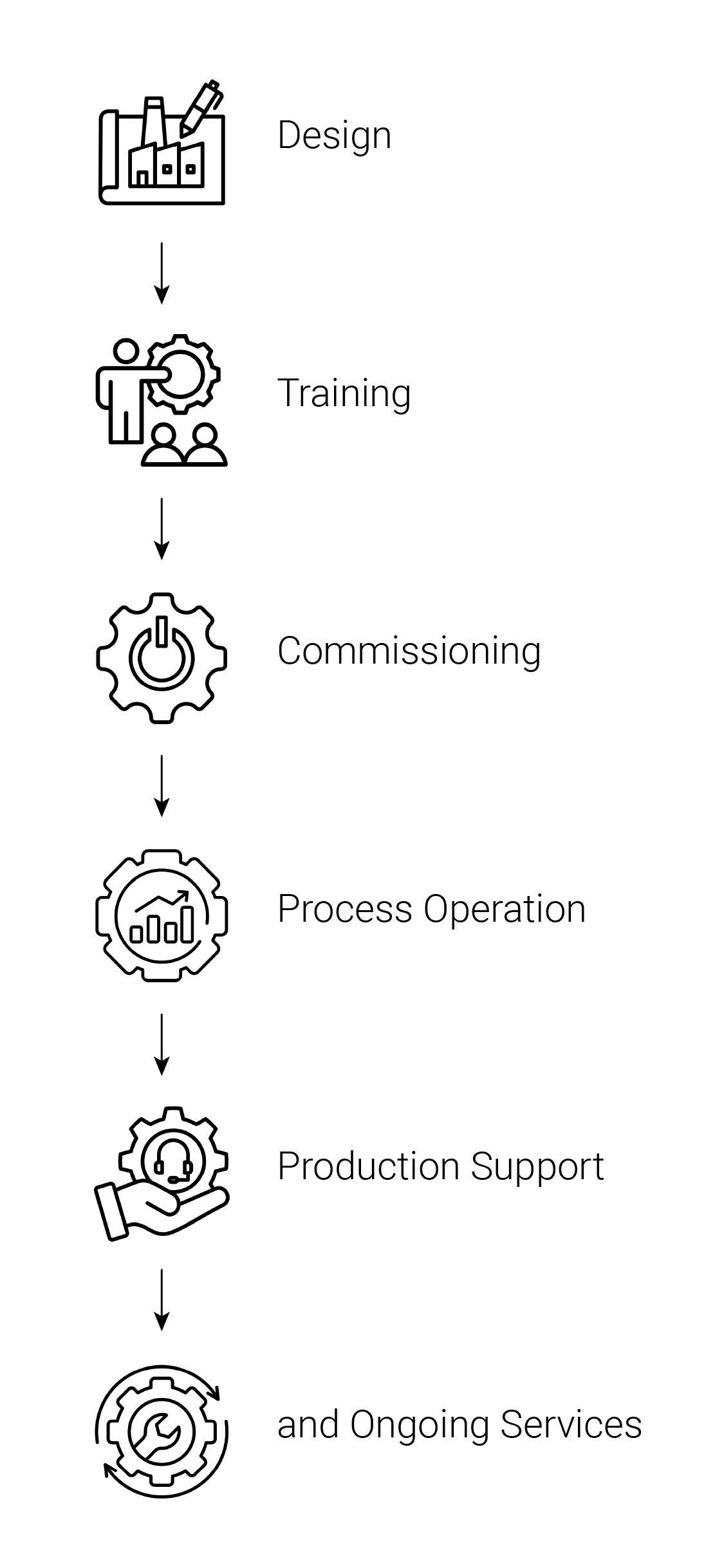

From Concept to Operation

As your technology partner, we manage the entire process from:

design,

training,

commissioning,

process operation,

production support

and ongoing services

to ensure a profitable GRP manufacturing plant.

From Concept to Operation

As your technology partner, we manage the entire process from:

to ensure a profitable GRP manufacturing plant.

E-CFW Production Lines

Find the E-CFW production line that fits your GRP manufacturing requirements

E-CFW ND 400-4000 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 400-4000 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 400-4000 mm.

| YEARLY OUTPUT: | 30.000 | tons |

| YEARLY OUTPUT (BASED ON ND 900) : | 250 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 2000 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 3000 | m² |

| FITTING AREA: | 2000 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 30.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 650 | kW |

| AVERAGE CONSUMPTION: | 180 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 20 | tons |

| MOVABLE AERIAL PLATFORM: | 10 | m |

| FORK LIFT FOR PIPE HANDLING: | 20 | tons |

E-CFW ND 300-3000 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 300-3000 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 300-3000 mm.

| YEARLY OUTPUT: | 21.000 | tons |

| YEARLY OUTPUT (BASED ON ND 900) : | 250 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 2000 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 2500 | m² |

| FITTING AREA: | 1500 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 25.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 550 | kW |

| AVERAGE CONSUMPTION: | 150 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 12 | tons |

| MOVABLE AERIAL PLATFORM: | 9 | m |

| FORK LIFT FOR PIPE HANDLING: | 10 | tons |

E-CFW ND 300-2600 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 300-2600 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 300-2600 mm.

| YEARLY OUTPUT: | 21.000 | tons |

| YEARLY OUTPUT (BASED ON ND 900) : | 250 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 2000 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 2500 | m² |

| FITTING AREA: | 1500 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 25.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 550 | kW |

| AVERAGE CONSUMPTION: | 150 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 10 | tons |

| MOVABLE AERIAL PLATFORM: | 9 | m |

| FORK LIFT FOR PIPE HANDLING: | 10 | tons |

E-CFW ND 300-1800 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 300-1800 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 300-1800 mm.

| YEARLY OUTPUT: | 21.000 | tons |

| YEARLY OUTPUT (BASED ON ND 900) : | 250 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 2000 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 2500 | m² |

| FITTING AREA: | 1500 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 20.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 450 | kW |

| AVERAGE CONSUMPTION: | 120 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 10 | tons |

| MOVABLE AERIAL PLATFORM: | 9 | m |

| FORK LIFT FOR PIPE HANDLING: | 10 | tons |

E-CFW ND 300-1400 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 300-1400 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 300-1400 mm.

| YEARLY OUTPUT: | 18.000 | tons |

| YEARLY OUTPUT (BASED ON ND 900) : | 250 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 2000 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 2000 | m² |

| FITTING AREA: | 1000 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 15.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 350 | kW |

| AVERAGE CONSUMPTION: | 120 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 8 | tons |

| MOVABLE AERIAL PLATFORM: | 7 | m |

| FORK LIFT FOR PIPE HANDLING: | 8 | tons |

E-CFW ND 300-600 PRODUCTION LINE

DESCRIPTION

The E-CFW ND 300-600 is designed to manufacture GRP (Glass Reinforced Pipes) in compliance with the main International Standard Specifications for water and sewer pipes for the range ND 300-600 mm.

| YEARLY OUTPUT: | 18.000 | tons |

| YEARLY OUTPUT (BASED ON ND 600) : | 260 | km |

| MAX ADVANCED SPEED: | 60 | m/h |

| QUALIFIED PRODUCTION SPEED: | 50 | m/h |

MAIN REQUIREMENTS

COVERED AREA REQUIREMENT:

| DRY RAW MATERIAL AREA: | 1500 | m² |

| CHEMICAL RAW MATERIAL AREA: | 800 | m² |

| PRODUCTION AND TESTING AREA: | 2000 | m² |

| FITTING AREA: | 1000 | m² |

UNCOVERED AREA REQUIREMENT:

| STOCK AREA FOR PIPES: | 10.000 | m² |

POWER SUPPLY:

| INSTALLED POWER: | 300 | kW |

| AVERAGE CONSUMPTION: | 100 | kWh |

COMPRESSED AIR SYSTEM:

| PRESSURE: | 7,5 | bar |

| CAPACITY: | 400 | Nm³/h |

FIREFIGHTING SYSTEM:

| A firefighting network and hydrants are to be installed following local standards and bylaws, as well as TOPFIBRA’s standard suggestions. |

HEAVY LIFTING AND HANDLING EQUIPMENT:

| TRAVEL CRANE FOR PRODUCTION AREA : | 5 | tons |

| MOVABLE AERIAL PLATFORM: | 5 | m |

| FORK LIFT FOR PIPE HANDLING: | 10 | tons |

Equipment for E-CFW Production Line

Explore the equipment powering E-CFW production lines

PRODUCTION EQUIPMENT

| E-CFW – Effective Continuous Filament Winding Machine | View Full Specifications | ||

| E-CWS – Coupling Winding System – Only for Full Face Coupling production | View Full Specifications | ||

ANCILLARY EQUIPMENT

| E-OCG – Offline Cutting and Grinding | |||

| E-PTT – Pipe Transport Trolleys – depending on the Layout configuration | View Full Specifications | ||

| E-PRW – Roller way – depending on the Layout configuration | View Full Specifications | ||

| E-CJM – Coupling Joining Machine | View Full Specifications | ||

| E-CGM – Coupling Grooving Machine – Only for Reka Coupling production | View Full Specifications | ||

| E-DBM – Coupling Deburring Machine – Only for Full Face Coupling production | View Full Specifications | ||

TESTING EQUIPMENT

| E-PHTM – Pipe Hydrostatic Testing Machine | View Full Specifications | ||

| E-CHTM – Coupling Hydrostatic Testing Machine | View Full Specifications | ||

LABORATORY EQUIPMENT

| E-TTM – Tensile Testing Machine | View Full Specifications | ||

| E-STM – Stiffness Testing Machine | View Full Specifications | ||

| E-SDTM – Split Disk Testing Machine | View Full Specifications | ||

The Key to Your Success Lies in Our E-CFW Lines!

Learn more in our EFW® Blog

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production

We created a unique blog so you can read all about our EFFECTIVE FILAMENT WINDING® Technology in one place!

It is the FIRST and ONLY blog, dedicated exclusively to the EFW® TECHNOLOGY, which is the first and only approach that allows profit optimization in the Filament Winding industry.

You can read all about the implementation of the EFW® Technology, how it connects all stages of your production and ensures that you are able to produce the best possible product and increase your profit.

Click on the button below, bookmark our blog and be up to date with our exclusive articles dedicated to the EFFECTIVE FILAMENT WINDING® Technology.

Subscribe to our newsletter

Receive valuable information and great insights on Effective Filament Winding® GRP pipe production